HDPE is one of the most versatile and widely used plastics around the world, with known strengths and durability, coupled with its resistance to moisture. It is a thermoplastic based on petroleum and has a specific molecular structure that gives it a high strength-to-density ratio. It is both lightweight and strong, making it a great material for use in applications ranging from consumer goods to industrial components. Its durability and moisture resistance make high-density polyethylene the favorite choice among manufacturers and consumers who demand longevity at relatively affordable prices. Its lightweight and resilient properties of HDPE plastic make it of further value in eco-friendly designs that can easily be recycled and reused in various applications. Its high melting point and impact resistance make its value further elevated, for materials must withstand physical tension and temperature variation. In the sections that follow we will discuss what makes HDPE unique, dive into its properties, and try to understand why it has turned out to be such a winner in manufacturing.

What is HDPE Plastic?

HDPE is the abbreviation of high-density polyethylene. But what is HDPE plastic exactly? It is the term that has been used to refer to the petroleum-based thermoplastic polymer. It is strong relative to its density and appears almost linear with minimal branching on the microscopic level. In addition to this, tightly packed chains are formed, hence why it is one of the most durable polyethylenes without putting up the weight.

The development of HDPE began in the 1930s. Initially, it was used to insulate radar cables. Later years have seen it pass through numerous industries due to this plastic’s versatile and dependable material. High-density polyethylene will become even more useful considering the resistance against moisture and chemicals since the polymer does not absorb these materials and degrade in aggressive environments. This quality makes it particularly suitable for applications where clean and long-lasting products are essential, such as containers for food and beverages, detergent bottles, and piping systems. In addition to its strength, HDPE is also highly valued for being cost-effective and easy to recycle.

What are the Properties of HDPE Plastic?

HDPE plastic has its own special set of properties that have made it popular in an array of applications. The properties of plastics are as follows :

High Strength-to-Density Ratio

The HDPE linear structure and the density, ranging from 930 to 970 kg/m³, result in having high tensile strength combined with exceptional strength for its weight and hence is ideal for places where both durability and lightweight properties are so crucial.

Chemical and Corrosion Resistance

HDPE is an extremely powerful, resistant polymer to all chemicals, acids, oils, and solvents, making it suitable for containers, pipes, and underground applications where durability is of extreme importance. It holds rust-proof properties along with corrosion resistance, so it can be used effectively in outdoor furniture, waste bins, and playground equipment.

Excellent Moldability

HDPE does not melt at any point because of its melting point, hence it is very flexible in shape. It is thus very useful in consumer goods like food containers, bottles, and plastic lumber.

Non-Leaching and Food Grade

HDPE is FDA, NSF, and USDA approved. It does not leach chemicals, making it safe for food and beverage containers.

Recyclable and Environmentally Friendly

HDPE, which has resin code 2, is also very recyclable and even used in a lot of furniture products, automotive parts, and construction materials, thus qualifying it to be a very eco-friendly option even though it’s not biodegradable.

Value for Money and Easy Accessibility

HDPE is cost-effective and of high quality and supports sustainable manufacturing by replacing the heavier material that uses natural resources in business and industrial applications.

With these characteristics of strength, durability, and environmental friendliness, HDPE endures as one of the leading choices for countless applications across industries.

What are the Common Uses of HDPE Plastic?

HDPE has the advantage of versatility and offers wide scope usage within different businesses. The uses of HDPE plastic For this reason, outstanding properties in high density polyethylene contribute to ideal objects like bottles of shampoo, milk, and detergent wash. The most common application of high density polyethylene plastic is in making containers like food storage and chemical containers. The resistance of HDPE to chemicals and moisture ensures that the products stored inside are safe and intact. There is further evidence for the benefits of HDPE in exterior applications. Its strength, durability, and resistance to weathering make this material extensively used in producing outdoor furniture, recycling bins, and playground equipment. Recycled HDPE is typically found in applications like wood or plastic lumber that is used as composite and will only decrease the rubbish from the landfills resulting in greater eco-friendliness. With the increasing application of HDPE in different sectors, namely food service, retail and municipal parks, it stands to reason that high-density polyethylene continues to prove a critical material for modern manufacturers and designers.

Benefits of HDPE Plastic

The combination of the unique features of HDPE made it fit for all manufacturing sectors. The advantages of HDPE include its high strength-to-density ratio, resulting from a linear structure and low branching, which provides superior tensile strength compared to LDPE, meaning HDPE can carry heavy loads without distortion or breakage. HDPE’s moldability at high temperatures allows its shape to be used in a wide variety of applications such as food containers, corrosion-resistant pipes, and playground equipment, and its high melting point provides high tenacity and maintains the integrity of products. HDPE has excellent resistance to water, acids, mold, and mildew. This implies that it is long-lasting and can withstand various environmental conditions, even for outdoor and underground applications. Recycling supports sustainable manufacturing; therefore, HDPE is versatile and environmentally friendly across industries.

HDPE vs. Other Plastics

Comparison with other plastics Overall, HDPE possesses strong advantages which have made it very suitable for a wide range of applications. The linear molecular structure confers a high strength-to-density ratio and an excellent tensile strength compared to LDPE and even polypropylene because it will be able to resist much more stress without deforming under load. HDPE resists acids, bases, and solvents very well. Therefore, there is no better plastic for the storage container and piping. Its higher melting point offers heat stability which provides the possibility to reuse and recycle without quality degradation, while thermosetting plastics generally cannot be reused or recycled. Its recyclability and strong demand support a sustainable lifecycle in its usage within industrial sectors ranging from packaging to construction because of strength, chemical resistance, and advantages of HDPE in terms of environmental benefits.

Conclusion

All things considered, high-density polyethylene presents a very versatile and durable plastic that fulfills a great number of applications in almost all kinds of industries. Its outstanding properties, like a very high strength-to-density ratio, excellent environmental resistance, and ease of recycling, make HDPE a favorite material for both producers and consumers of sustainable solutions. It deals with the production of things taken to be used daily. A few examples include milk bottles and plastic bags, among others. In more technologically demanding applications, such as plumbing and outdoor furniture, this again brings out the advantages realized in HDPE plastic usage. This way, the benefits of HDPE along with its uses make an added bonus for businesses and people to opt for environmentally friendly practices with full performance in this exceptional plastic. In the end, HDPE represents a pragmatic solution for present needs as well as an initial step towards a more sustainable future.

FAQ's

Where is HDPE Commonly Used?

HDPE or high-density polyethylene is one of the highly versatile materials available in industries that have proved to be more robust and inexpensive for use. Household containers range from ordinary milk bottles, shampoo, detergent bottles, among many more. Pipelines and other containers, plus storage tanks and more constitute industrial application and construction sectors apply it as a material on plastic lumber, piping and piping systems that withstand chemical corrosion or corrosion from its environment. The inherent weather resistance and durability features of HDPE have made it the choice for most outdoor furniture, playground equipment, and marine products.

Is HDPE Plastic Recyclable?

Yes, HDPE is highly recyclable and thus marked with the recycling symbol and number 2. One of its very sustainable features is that it has a high recyclability: once its products are discarded, those HDPE products may be made into new things such as plastic lumber, pipes, recycling bins, and other HDPE containers. Therefore, recycling HDPE wastes reduces waste and conserves resources while facilitating a closed-loop economy. There are recycling facilities and many communities, which accept HDPE for recycling.

Can HDPE Be Used for Food Packaging?

Absolutely. HDPE is mainly applied in food packaging for it is safe, non-leak material and doesn’t harbor mold or mildew or odors. It is a superb milk jug, juice, or any other food storage. Chemical resistance and the very high melting point ensure a food or beverage stored there would neither lose quality nor become unsafe. Moreover, HDPE can be sterilized at elevated temperatures, which is the reason it has FDA approval for direct food contact applications.

What Are Plastic Granules? Meaning, Types, and Uses

What Are Plastic Granules? Meaning, Types, and Uses What is Thermoplastic? Examples & Key Benefits

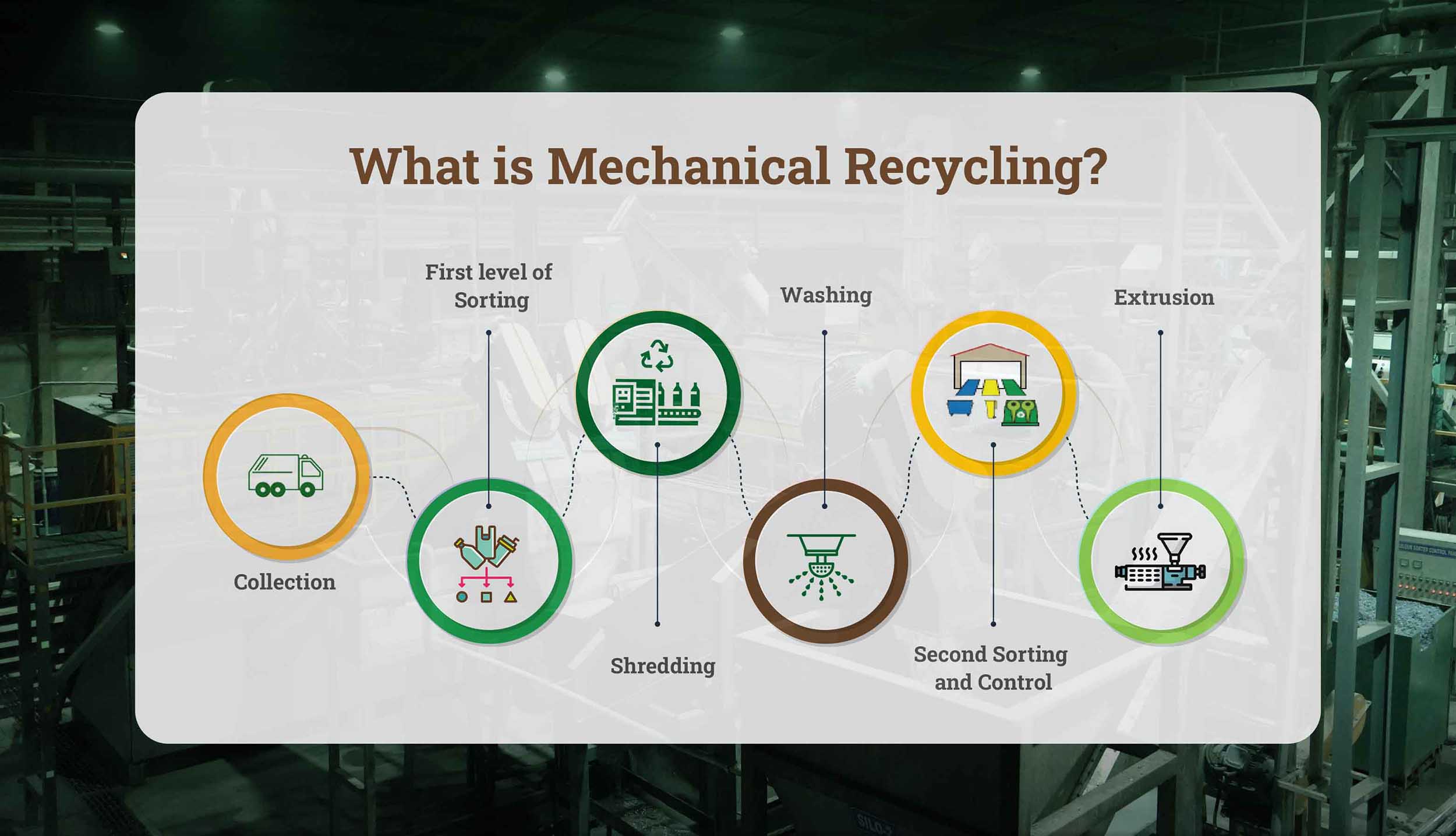

What is Thermoplastic? Examples & Key Benefits What is Mechanical Recycling? Steps, Benefits & Challenges

What is Mechanical Recycling? Steps, Benefits & Challenges What is Rigid Packaging Its benefits, and Examples

What is Rigid Packaging Its benefits, and Examples What is the Impact of Plastic on the Environment?

What is the Impact of Plastic on the Environment?