Thermoplastics are used in multiple industries such as packaging, automotive, construction and in the electronics industry etc.The adaptability, durability and wide range of applications of thermoplastics has revolutionized the manufacturing sector. In the packaging sector, thermoplastic is often a top choice because it can be heated, reformed and recycled. Other benefits of the use of thermoplastics in the plastic packaging sector are affordability, recyclability and cost-effectiveness. A thorough understanding of the technical properties of a thermoplastic will assist industries in making correct decisions in terms of material choices for production.

What is Thermoplastic?

Thermo plastics are a group of polymers that can be softened by the process of heating. It can be processed after heating by the use of techniques like injection moulding, thermoforming and blow moulding. Thermo plastic polymers consist of chains of linear molecular structures which help in retaining the molecular structure while melting or moulding. Most of the thermo plastics can be melted and recast almost indefinitely, unlike thermosetting plastics that involve irreversible chemical transformations. Thermosetting plastics cannot be remolded once the curing process is complete. The thermo plastic’s high impact resistance and flexibility characteristics make it an excellent and environment-friendly option for industrial use.

What are the examples of thermoplastic?

Examples of thermoplastics that are commonly used include:

- Polyethylene Terephthalate (PET)

- High-Density Polyethylene (HDPE)

- Polyvinyl Chloride (PVC)

- Low-Density Polyethylene (LDPE)

- Polypropylene (PP)

- Polystyrene (PS)

- Acrylic(PMMA)

- Polycarbonate(PC)

- Nylon(Polyamide, PA)

- Thermoplastic Polyurethane(TPU)

What are the advantages of thermoplastic?

The advantages of thermoplastics are as follows:

- Thermoplastics offer advantages of plastic recycling. The ability of reshaping and reusing makes the use an environmentally friendly choice. The application of plastic remolded from thermoplastics is endless.

- Thermoplastics can be cost efficient for manufacturing units as it is well suited for high volume low cost processes like extrusion and injection molding.

- Thermoplastics are impact resistant, this makes it ideal for applications requiring durability.

- Thermoplastics provide versatility in design. The mechanical properties allow it to be molded into complex geometries.

What are the properties of thermoplastic?

The properties of thermoplastics are as follows :

Thermal Reversibility

They become soft on heating and hard on cooling, enabling reshaping several times.

Lightweight

Thermoplastics are of low density, hence easy to handle and transport.

Durability

High impact strength and long-term performance under different conditions.

Flexibility

Can be molded into various shapes and forms for different uses.

Chemical Resistance

Most thermoplastics are resistant to oils, solvents, and chemicals.

Electrical Insulation

Outstanding insulating features for applications in electronic devices.

Recyclability

Most thermoplastics can be recycled, which has a positive impact on the environment.

What is thermoplastic used for?

Thermoplastics are highly adaptable and the applications of thermoplastics are numerous as listed below:

Polyamide Nylon

Used in car tyres, ropes, fish nets, tents, casings, bearings and gear components.

PVC (polyvinyl chloride)

Used in pipes, cabinets, toys, cable insulation, roofing, flooring etc.

PP (polypropylene)

Used in consumer durables, medical and lab equipment, kitchen utensils and food containers.

LDPE (Low density Polyethylene)

Used for packaging, toys, plastic bags, cement bags and film wraps.

HDPE (High density Polyethylene)

Used in plastic bottles, exterior of household goods, outdoor play equipment, acrylic sheets, polycarbonate sheets.

Acrylic

Commonly used as an alternative to glass and for items such as LED screens, furniture, vehicle headlights, paint and lenses

PS (polystyrene)

Used in packaging, toys, containers and foam cups.

PTFE (Teflon, Polytetrafluoroethylene)

Used for waterproof clothing, non-stick pots & pans, electrical equipment, disposable plates and trays

Conclusion

Thermoplastics have the power to play an essential role in embracing practices of sustainability as well as sustainable production. Through the use of thermoplastics various industries can phase out waste while reducing their footprint. With the consideration that the biggest threat to the ecosystem currently is single-use plastic, adopting the correct type of thermoplastics through effective recycling protocols can play an instrumental role towards the green world.

FAQ's

Is thermoplastic good for the environment?

Thermoplastics have both good and bad effects on the environment. The advantages of thermoplastics include that it can be recycled. This makes some uses of thermoplastics beneficial to the environment and supports a circular economy. Certain types of thermoplastic such as polyethylene (PE) and polystyrene (PS) are non-biodegradable and do not decompose in nature, and result in a bad impact on the environment.

Are Thermoplastics Recyclable?

The advantages of thermoplastics such as PET and HDPE are that they are recyclable. They can be reformed and re-melted many times. Nevertheless, sound practices of recycling are critical in order to realize the maximum good to the environment.

Are Thermoplastics Biodegradable?

Most thermoplastics possess the characteristics of being not biodegradable since they are designed to be used for a long time and to last long. Applications of thermoplastics like polypropylene and polystyrene can last for centuries in landfills.

What is Thermoplastic? Examples & Key Benefits

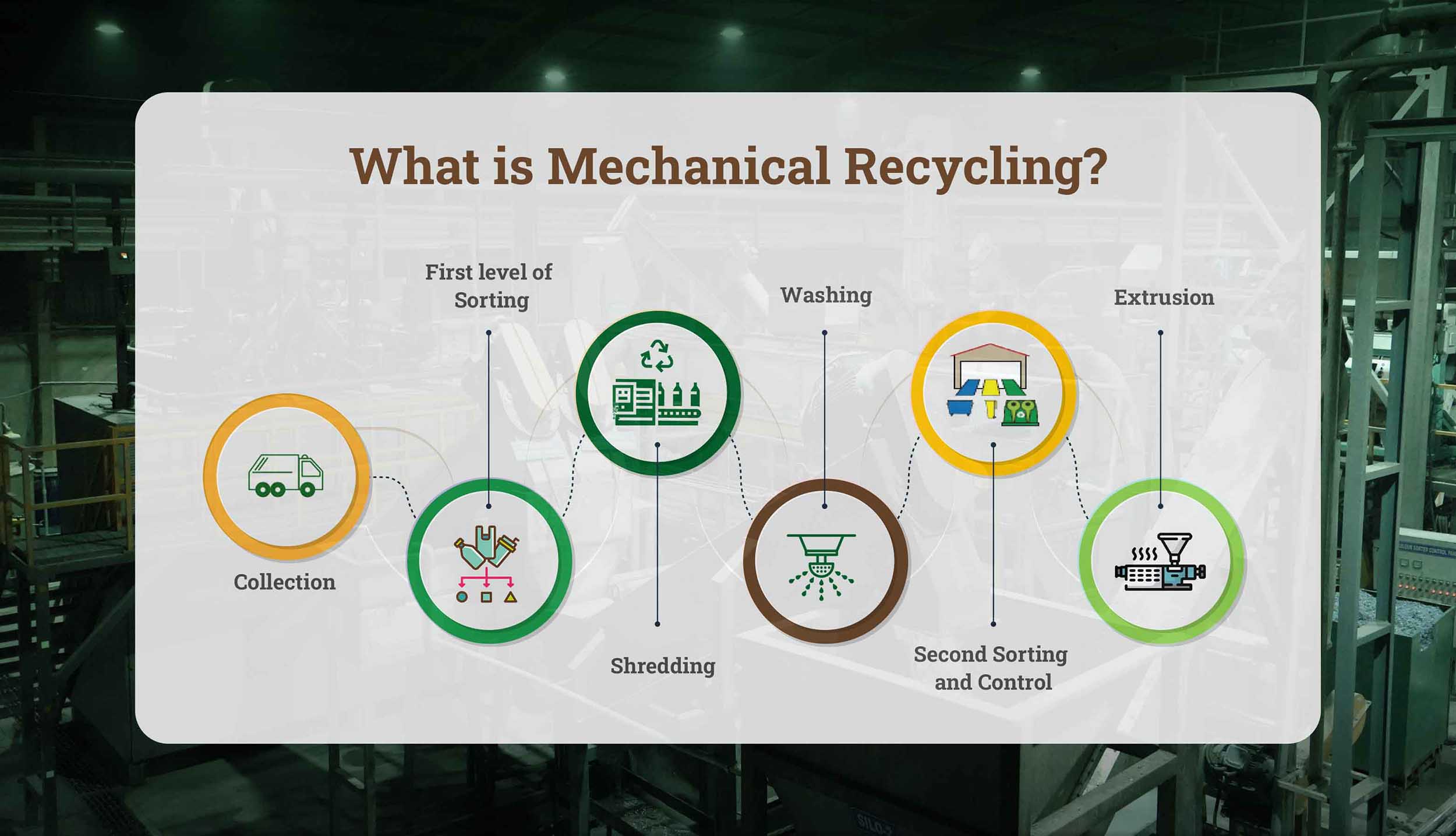

What is Thermoplastic? Examples & Key Benefits What is Mechanical Recycling? Steps, Benefits & Challenges

What is Mechanical Recycling? Steps, Benefits & Challenges What is Rigid Packaging Its benefits, and Examples

What is Rigid Packaging Its benefits, and Examples What is the Impact of Plastic on the Environment?

What is the Impact of Plastic on the Environment?  Plastic Waste Management Rules in India

Plastic Waste Management Rules in India